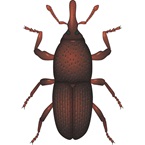

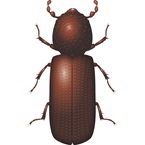

Order: Coleoptera (‘sheath-wings’)

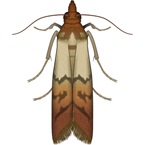

Family: Silvanidae

Grain Beetles:

3mm long

CHARACTERISTICS:

Forewings hard and leathery, meeting along midline of dorsal surface; hindwings membranous, sometimes lacking; biting mouthparts; welldeveloped thorax; complete metamorphosis with egg, larval, pupal and adult stages. Narrow, flattened insects with 11-segmented, clubbed antennae and 5-segmented tarsi.

SPECIES CHARACTERISTICS:

Saw-Toothed Grain Beetle (Oryzaephilus surinamensis)

Adults, 2.5-3.5mm long; colour: dark brown; distance from eye to prothorax more than half vertical diameter of eye; 6 teeth along each side of prothorax (hence the name ‘Saw-toothed’).

AREAS WHERE FOUND:

As indicated by its species name, which is taken from Surinam, the Saw-toothed grain beetle probably originated from the Americas. It is now cosmopolitan in distribution. The species will infest cereals and a wide range of foodstuffs. Retail premises and warehouses can suffer infestations and the beetles will frequently appear in packaged food. Infestations arise from the presence of insects in the fabric of grain stores (including sacks), in grain being transferred from one establishment to another and in vehicles used for transportation. Relatively small numbers of insects can rapidly give rise to serious infestations. They are small, active insects which readily exploit cracks and crevices where they can hide. Being cold-hardy they are able to overwinter in temperate lands without difficulty. Their life-cycle may be completed in as little as 20 days and serious outbreaks may occur within a month of harvest. The Merchant grain beetle is also widely distributed. Like the Saw-toothed grain beetle, it too will infest a wide variety of foodstuffs. However, since it is more sensitive to low temperatures and humidities, infestations only become established in heated buildings where suitable conditions exist. The Foreign grain beetle also originated in the tropics. It is capable of infesting a variety of materials but only in the presence of moulds.

IMPORTANCE AS A PEST:

Saw-toothed grain beetles are potentially important pests of farm-stored grain. They also infest cereal products, dried fruit, dried meats, oilseeds, nuts, rice and even drugs. In grain, the mere presence of insects may result in its rejection. The germ may be damaged and when infestations become heavy they cause the grain to heat. This in turn leads to caking, moulding and even sprouting. Both the quality and weight of the grain may be reduced. Malting barley may be rejected because of poor germination, whilst milling wheat is adversely affected by tainting and discoloration. The presence of insects in other foodstuffs will render them unpalatable and cause their rejection. Merchant grain beetles mainly infest oilseeds and dried fruit whilst Foreign grain beetles attack cereal products and cocoa as well as these commodities.

LIFE-CYCLE:

The female Saw-toothed grain beetle lays up to 400 eggs, either singly or in small batches, at a rate of 6-10 per day. These are laid in, or adjacent to, a suitable food supply and at a temperature of 20-23°C hatch in 8-17 days to give flattened larvae about 0.9mm long. They are yellowishwhite in colour, with brown flecks and a brown head. Typical of coleopterous larvae, they have a well-developed head, biting mouthparts and 3 pairs of legs on the thoracic segments. The larvae are active and feed on damaged grains, so they can be regarded as secondary pests of grain. The larval stage lasts 4-7 weeks during which the larvae go through 2-5 moults, attaining a length of 3mm. They then construct a cell of food particles and other debris in which to pupate, emerging after 1-3 weeks as adults. On emergence the adult beetles live for 6-10 months, breeding within a temperature range of 17.5-40°C. At 20°C the full life-cycle is completed in 12-15 weeks whilst at 32-35°C it takes only 20 days.

CONTROL:

Assessment of infestations

A variety of trapping techniques are available for measuring stored product beetle infestations. These include pit fall traps, bait bags, insect probe traps and adhesive traps. Whatever system is employed adequate records must be kept.

- Hygiene/management

Stores should be soundly constructed to ensure maintenance of correct storage conditions and allow for easy cleaning. They should be insulated, well ventilated and damp-proof. Cracks and crevices, which may provide harbourages for the beetles, should be kept to a minimum. Commodities should be stacked neatly above the floor level using pallets, away from walls and should not touch the ceiling. A gap between stacks will allow for ventilation, regular inspection, cleaning

and, if necessary, treatment with insecticides (see recommended products). Appropriate stock rotation is important and if possible there should be a one-way passage of commodities through the premises. The careful choice of packaging can help to deter insect attack. Generally, thick, tough materials with a smooth, shiny finish are preferred. Packs should be strong and well sealed. It is important to ensure that there are no food residues (stored commodities or secondary sources, e.g. birds’ nests) in which beetles can breed and develop to infest new materials. All infested commodities should be destroyed or fumigated. Stores should be kept scrupulously clean and farm stores should be thoroughly cleaned before harvest. All grain taken into store should be dried to a suitable moisture content (MC) and temperature e.g. <15%MC and <15°C and maintained in that condition.

- Insecticidal control:

Insecticides (see recommended products) can be applied to the fabric of stores concentrating on potential insect harbourages. Alternatively it may be appropriate to employ grain protectants.

Prothorax: First thoracic segment.